Model Foundry Open Source

The operating system for your additive manufacturing workflow. Catalog, track, and assemble complex hardware projects with precision.

Why File Explorers Fail at Making

We've all been there: a folder full of `part_v2_final_REAL.stl` files, a spreadsheet for screws and magnets, and a YouTube video for assembly instructions. It's a mess.

Building complex 3D printed projects requires more than just files. It requires checking material quantities, tracking purchased hardware, and following step-by-step assembly guides. Model Foundry unifies this chaos.

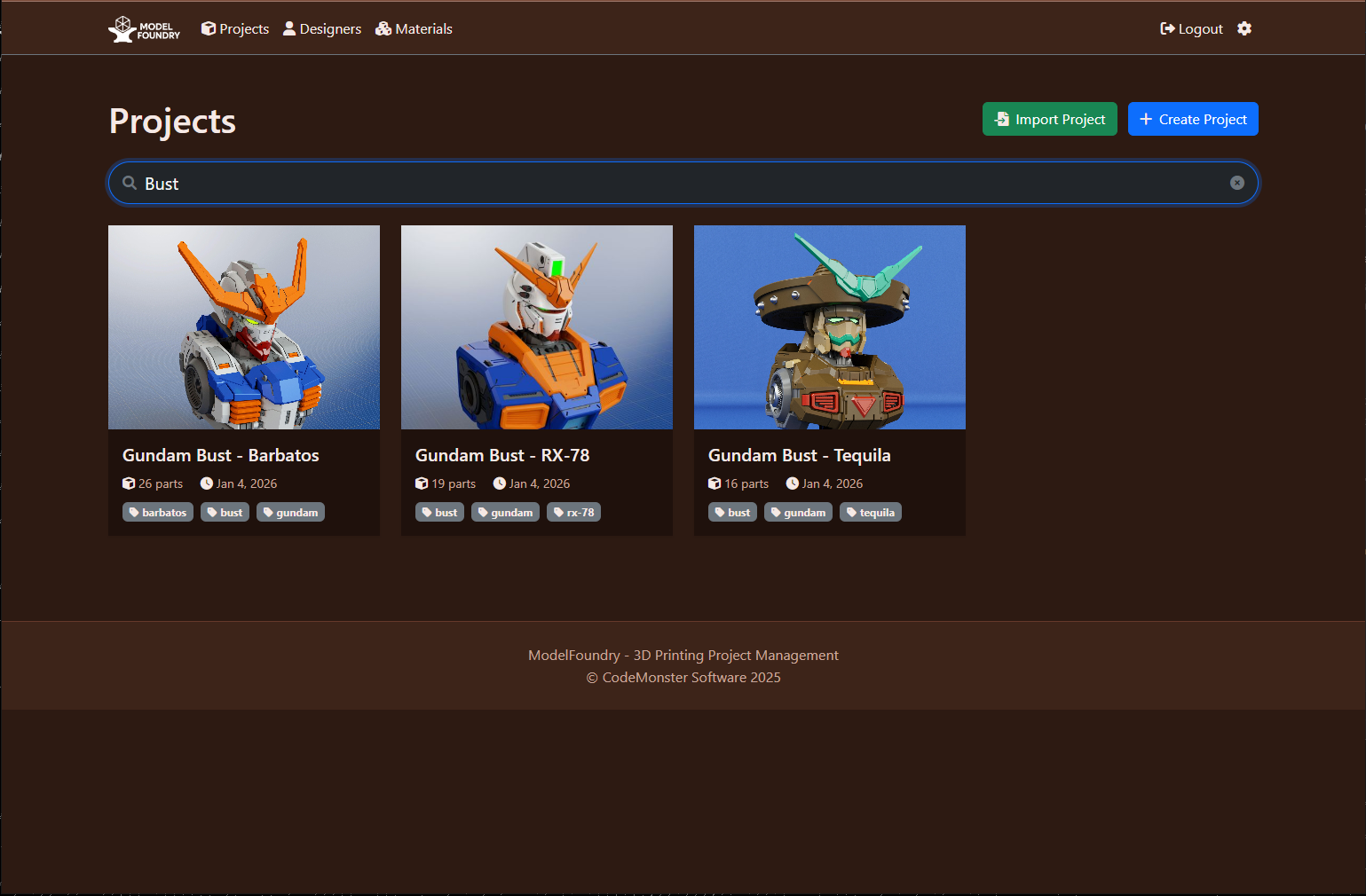

Project-First Logic

Stop thinking in files. Start thinking in Projects. Group multiple parts, sub-assemblies, and variations under a single logical entity. Assign designers and track version history for the entire build.

Hardware BOM Tracking

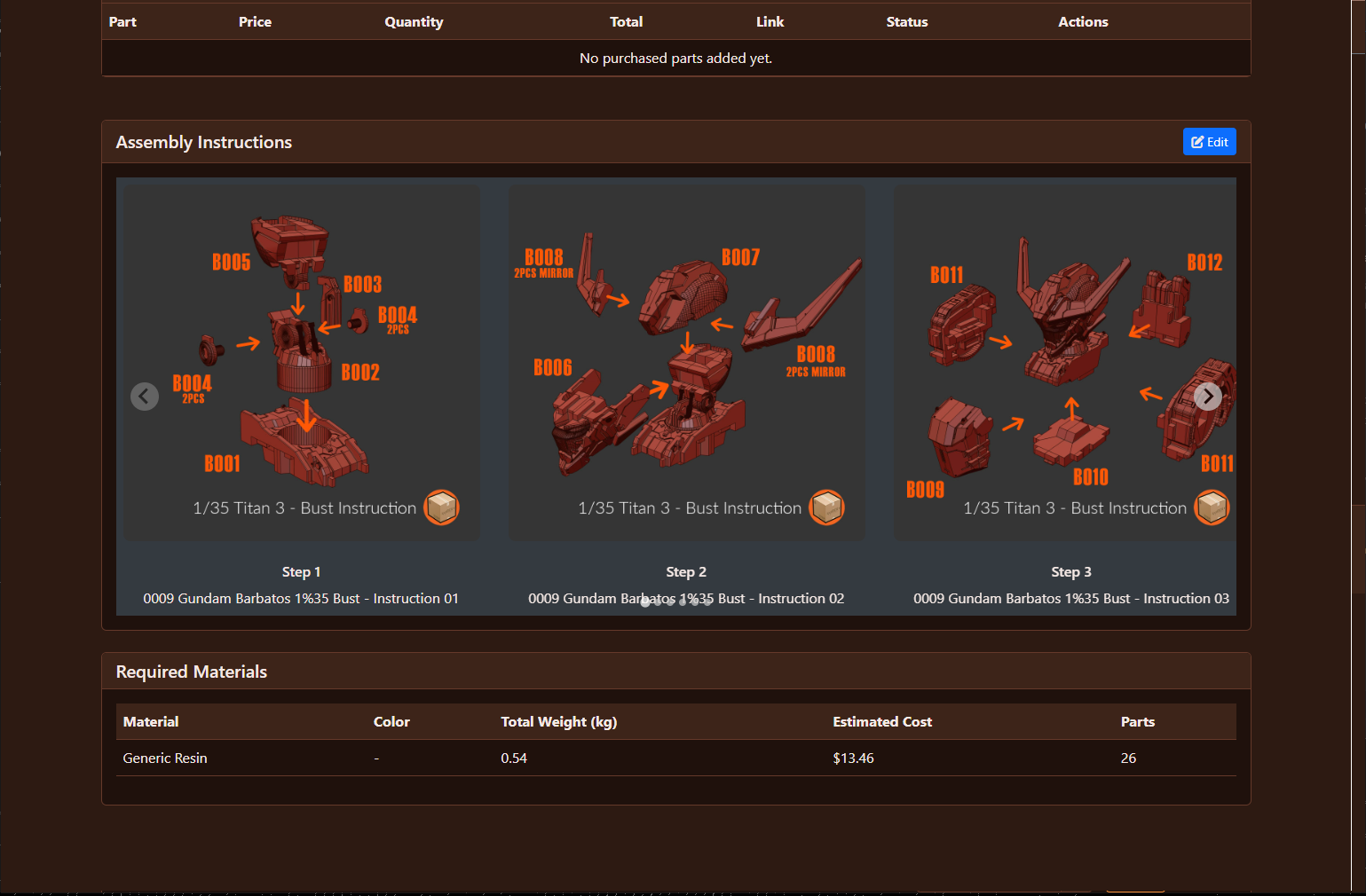

A project isn't just plastic. Track every M3 screw, bearing, and stepper motor required. Link directly to purchase pages and calculate total build costs before you even slice a file.

Material Intelligence

"Do I have enough grey PLA?" Model Foundry calculates total filament weight across all parts in a project and checks it against your inventory, preventing mid-print runouts.

Built for Builders

Intelligent Cataloging

Multi-Part Assemblies

Organize massive projects (like Voron printers or cosplay armor) into manageable sub-components. No more digging through hundreds of flat files.

Designer Management

Credit where credit is due. Associate projects with their original creators, link to their portfolios, and group projects by designer.

Robust Search & Tagging

Find "that one bracket" instantly. Rich tagging (e.g., "#structural", "#PETG", "#requires-support") makes retrieval effortless.

Inventory & Procurement

Hardware Sourcing

Create a "Shopping List" for every project. Track purchased vs. missing items (screws, magnets, electronics) with direct links to vendors.

Filament Estimation

Automatically sum the weight of all printed parts. Know exactly how many spools of Red ABS you need before you start.

Digital Assembly Guide

Integrated Documentation

Upload PDFs, images, and Markdown guides directly alongside the files. No more switching tabs to find the assembly steps.

Video Embedding

Embed YouTube assembly tutorials right in the project dashboard. Watch the guide while you build.